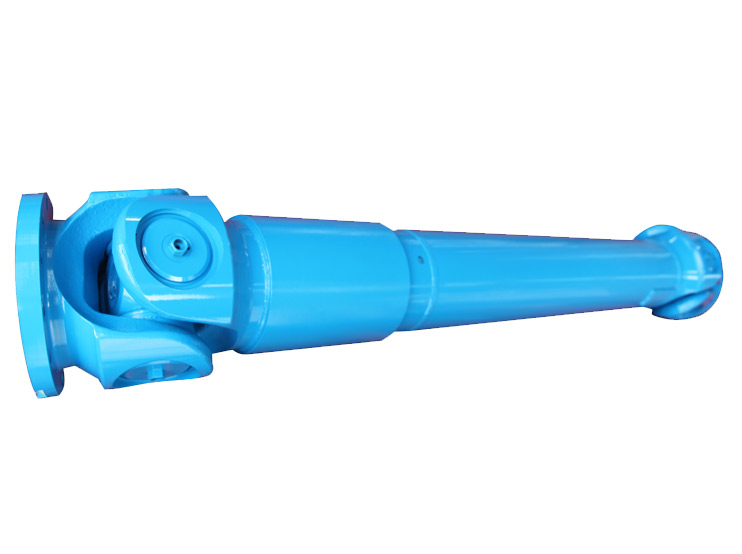

Universal couplings make use of the characteristics of its mechanism, so that the two axes are not in the same axis, the existence of the axis of the case of the angle can be realized by the coupling of the two axes of continuous rotation, and reliable transmission of torque and motion.

The biggest characteristic of universal coupling is: its structure has larger angular compensation ability, compact structure, high transmission efficiency.

The angle between the two axes of different structural types of universal couplings is not the same, generally between 5°-45°.

Universal coupling has various structural types, such as: cross shaft type, ball cage type, ball fork type, bump type, ball pin type, ball hinged type, ball hinged plunger type, three-pin type, three-forked rod type, three-ball pin type, hinged rod type, etc.; the most commonly used for the cross-axis type, followed by the ball cage type.

In practice, they are categorized as heavy duty, medium duty, light duty and small duty according to the size of the torque transmitted.

Universal coupling connects two shafts that are not in the same axis, so that they can operate at an angle and in the same axis, playing a connecting shaft, the role of undertaking.

Generally used in the coupling and the working machine before connected. Universal shaft has a variety of styles, length, spline, and the different forms of connection, universal coupling will naturally be different according to the different universal shaft.

Because the coupling is a connection, it will be required to fit over the cardan shaft to make the connection.

If you have questions or insights in this regard, you can contact us, we will give you professional service.