Product Details

In metallurgy, mining, chemical industry, cement and other industrial sectors, every year there are a large number of raw materials and reuse of waste materials need to be processed by crusher.

For example, in the ore dressing plant in order to make the useful minerals in the ore to achieve monomer separation, it is necessary to use the crusher to crush the raw ore to the particle size required by the grinding process.

Crushing machinery is needed to crush the raw material to the particle size required for the next operation. In coking plants, sintering plants, ceramic plants, glass industry, powder metallurgy and other sectors, crushing machines are required to crush raw materials to the required size for the next operation.

In the crusher complete set of operating equipment as one of the important transmission system, i.e. crusher universal shaft selection is very important.

Because the crusher industry’s working conditions are generally more severe, to ensure the long-term stable operation of the entire transmission system is the first guarantee.

The universal shaft of scrap crusher/PSX crushing line/crusher universal shaft is widely used in the transmission system of crusher, connected to the output of high-pressure motor and the input of knife shaft.

Crusher cardan shaft in the calculation of selection to select a certain safety factor, of course, not the larger the model the better, but to choose the appropriate, generally we recommend according to the motor output torque of three times to choose; because the crusher working state is extremely unstable, the knife shaft bearing torque and the size of the waste material, the number of waste materials, waste material thick and thin, as well as the type of waste material has a great relationship, We cardan shaft engineers have a lot of experience, have developed the PSX universal shaft.

We have developed the PSX series 2000hp, 4000hp, 6000hp, 8000hp universal shafts for crusher, and cooperated with domestic crusher manufacturers, such as Lidi, Huahong, Luyou, etc.

At the same time, We also developed 450KW, 630KW, 900KW and other small crusher shafts, which can meet the needs of the small-scale scrap steel production enterprises.

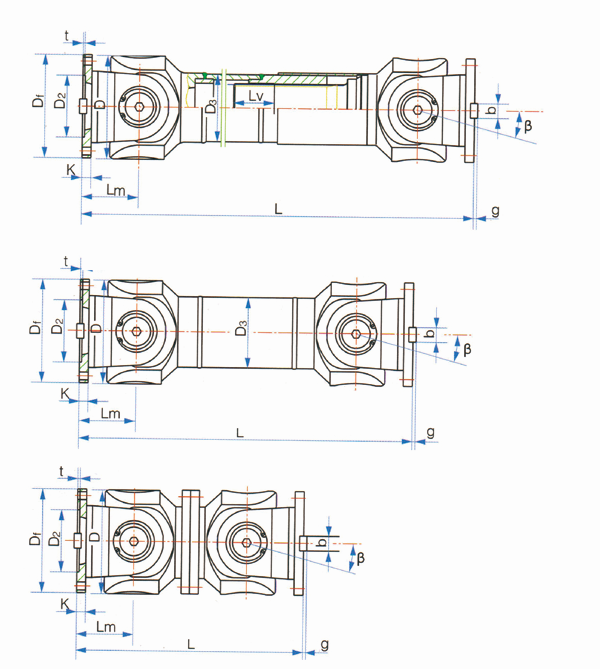

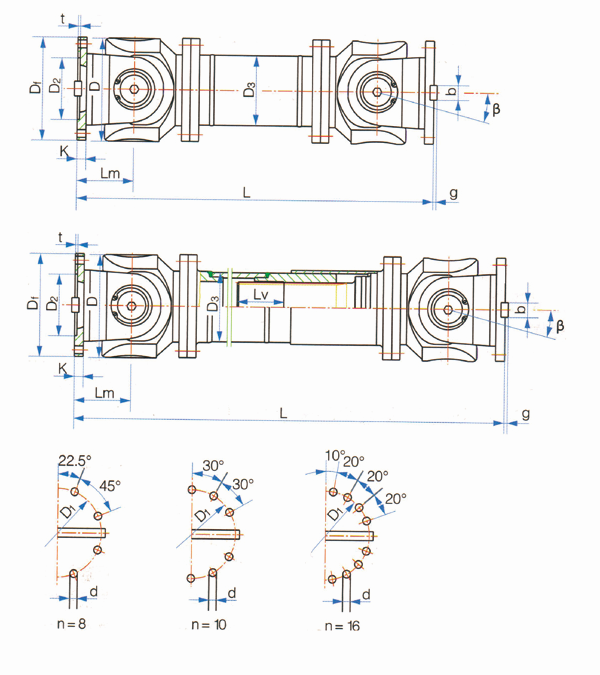

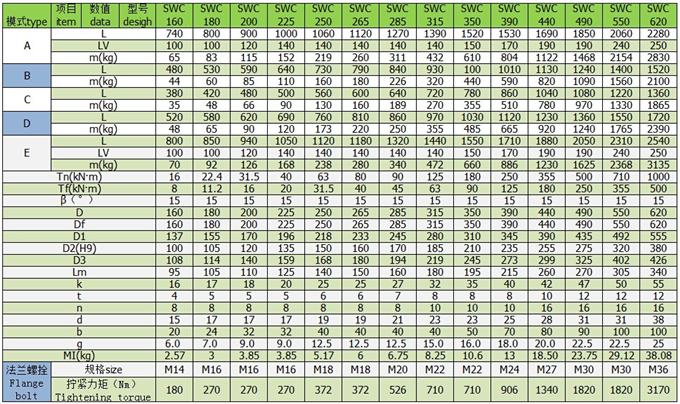

Note: 1. The meaning of each code in the above table is as follows:

L – standard length, for the telescopic type, the length L is the minimum length in the shortened state;

Lv – elongation;

m–Mass;

Tn – nominal torque (take 50% of the yielding torque);

Tf–Fatigue torque, i.e. the permissible torque determined by fatigue strength under variable bending load;

β – the maximum axis folding angle;

mL – the mass of the growth of 100mm.

- The above table does not specify the unit of measurement according to millimeters;

- Users need to change the standard length, expansion and flange type dimensions, please set with our manufacturers.

At present, the development of the crusher industry is stable, from the point of view of the national industrial policy and the industry’s operating environment, the expansion of domestic demand required by the new policy in recent years, is bound to drive the development of crusher enterprises, and bring new opportunities for the development of crusher enterprises.

Due to the continuous development of downstream industries such as mineral industry, chemical industry and construction industry, China’s crusher market demand is more stable, so the overall development of the industry is relatively stable.

At the same time, the new high-speed rail in the second and third tier cities will drive the steel market and stone and other building materials industry rebound, which also drives the development of crusher stone production line and iron ore beneficiation production line.

We company and a number of crusher equipment manufacturers to reach a long-term cooperative relationship, we provide crusher universal shaft selection, universal shaft parameter design research and development and universal shaft production and other one-stop service.

We provide one-stop service of crusher cardan shaft selection, cardan shaft parameter design and development, and cardan shaft production, etc. We supply crusher cardan shaft directly from the manufacturer, which saves your time, effort and worry, and we sincerely hope that we can get your recognition of our crusher cardan shaft quality.